Research Service

5-Step Research Process

Step 1 : Commercial Catalysts Research

– Catalyst Development

– Long time Stability Test

Step 2 : Conceptual Process Design

• Basis of design

• Conceptual process design

• Economic evaluation

• Sensitivity study

• Target Process development

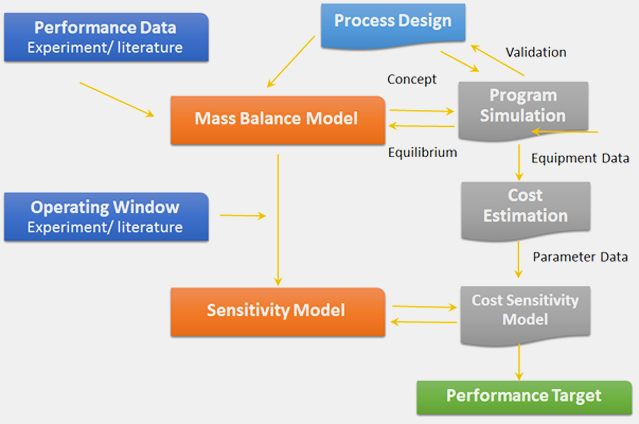

Conceptual process design

– Material balance model and linked with costing

– Process design and validation (simulation program)

– Scaling of each equipment in process

– Cost estimation

– Equipment cost and capital investment cost

– Utility consumption cost

– Sensitivity model with parameter variation

– Next research target

Cost Estimation (EBITDA)

– Total Module Cost (pump, Heat Ex., Vessels, Furnace, etc.)

– Total Capital Cost (Contingency 15%, Fee 3%)

– Total grass roots capital (Land, site, facility, building 60%)

– Startup & working capital

– Cost of Regeneration & Replacement

– Raw material, By-product and Utility Cost

– Operating Cost

– Maintenance & repairs

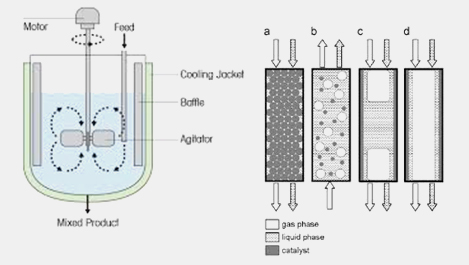

Step 3 : Reaction Proof

• Fixed Bed Reactor Size 1/4”-1/2”

• Mixing Tank Size 1 Liter

• Benchmarking catalyst

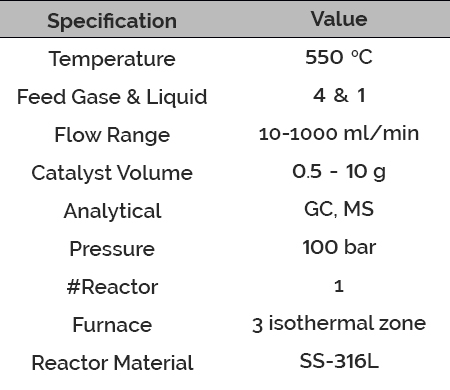

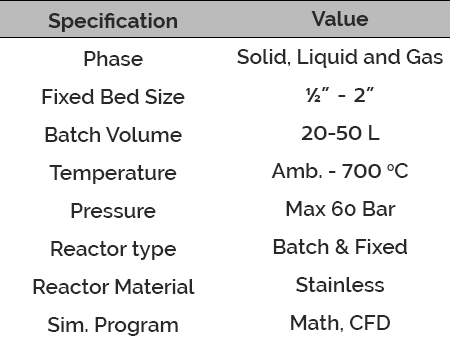

Kinetic Reactor Specifications

Step 4 : Scalable Kinetic Research

• Research/Test for Scalable Intrinsic or Global Kinetics

• Catalyst testing under industrial conditions

• Benchmarking catalyst

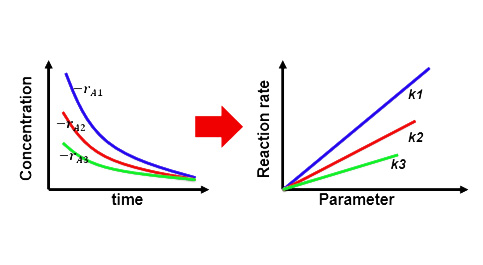

Understand Scalable Kinetic Reaction

Objective for Kinetic Determination:

– To Determine Reaction Mechanism of Main and Side RxNs

– To Determine Reaction Rate of Main and Side RxNs Factors Influencing Rate of Reaction

– Concentration or Flowrate of Reactant

– RxN Temperature

– RxN Pressure

– Catalyst

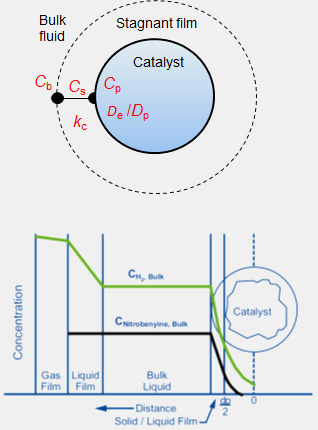

Type of Kinetic

– Intrinsic Kinetic: Kinetic of Elementary RxN w/o Mass-Heat

– Overall Intrinsic Kinetic: Kinetic w/o Mass-Heat Effect

– Global Kinetic: Kinetic w/ Mass and Heat Transfer Effect

Benefits of Scalable Kinetic Catalyst Development

– Certainly true kinetic for application

– Highly turbulent reactor to eliminate heat & mass transfer effect

– Main-Side Reaction and Heat of reaction determination

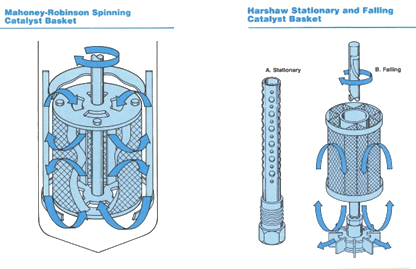

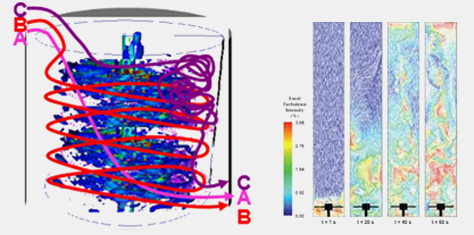

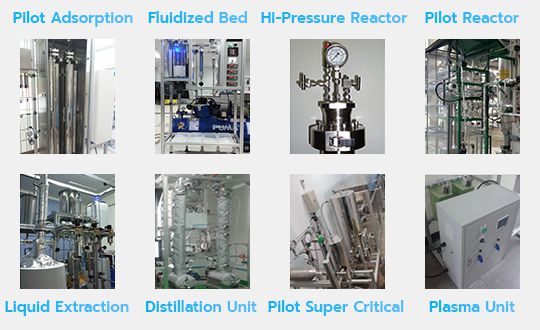

Step 5 : Hydrodynamic Scale up Research

– Research/Test Process Scale up by Pilot-Plant Process

– Catalyst testing under industrial conditions with Pilot Scale

– Produce excellent data quality allowing for kinetic studies and modelling (CFD) Pilot

Fixed-Batch Reactor Specifications

– Reactive distillation increase product yield

– Membrane separation increase conversion and product yield

– Supercritical water gasification by continuous flow reactor

– Rotating fluidized bed reactor for polymerization – Etc.

– Get Real Commercial design to scale up/ down reactor

– Process development and optimization with wider range of parameters and closer to industrial conditions

– Technical and Scientific consulting from Commercial Plant during the scale-up process