GLOBAL R&D IS THE SALES REPRESENTATIVE

Liquid Penetrant Testing (PT) MR85 MR62 MR70I

ตรวจจับรอยรั่วคราบน้ำมัน

Magnetic Particle Testing (MT) MR79 MR72 MR76S

น้ำยาตรวจสอบรอยร้าวที่มองไม่เห็น น้ำยาตรวจสอบพื้นผิว น้ำยาตรวจสอบแนวเชื่อม น้ำยาตรวจสอบแรงเครียด สเปรย์ทดสอบรอยร้าว น้ำยาเช็ครอยร้าว น้ำยาเช็ครอยร้าวแนวเชื่อม

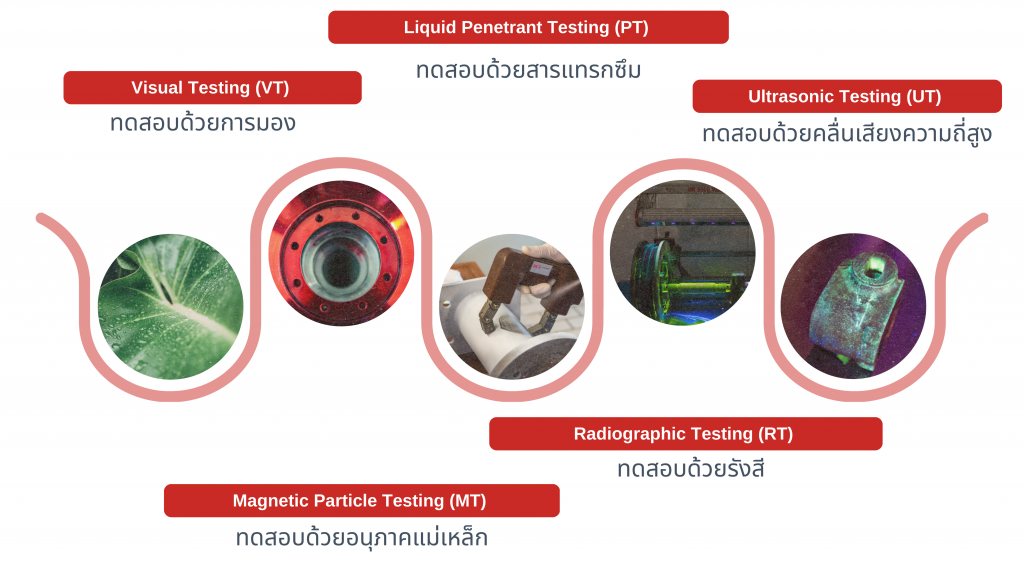

ทดสอบด้วยสารแทรกซึม ทดสอบด้วยการมอง ทดสอบด้วยคลื่นความถี่สูง ทดสอบด้วยรังสี ทดสอบด้วยอนุภาคแม่เหล็ก

น้ำยาตรวจสอบรอยร้าวด้วยอนุภาคแม่เหล็ก จำหน่ายอุปกรณ์ทางวิศวกรรม น้ำยาตรวจสอบรอบร้าว รอยเชื่อม แบบไม่ทำลาย ด้วยอนุภาคแม่เหล็ก และสารแทรกซึมแบรนด์ MRChemie

OUR PRODUCTS

PENETRANT TESTING

With our products in the area of penetrant testing, surface defects on components and machines can be detected quickly and easily in ferrous and non-ferrous metals, many plastics, ceramic materials, glass, etc.

MAGNETIC PARTICLE INSPECTION

Our products in the field of magnetic particle testing are used to detect mainly gap-like material separations (e.g. cracks) in the surface and in the near-surface area.

Ferromagnetic materials can be tested. To use the magnetic powder process, the workpiece must be magnetized in the test section.

ECO-LINE

Our ECO-Line products are the answer to the increasingly important topic of sustainability.

They do not require labeling and are biodegradable.

UV-TECHNOLOGY

Our UV lights are primarily used in non-destructive crack testing (NDT), especially in penetration and magnetic particle testing.

MR® UV lights are based on the long-lasting and energy-efficient LED technology and were specially developed for industrial use.

EQUIPMENT

Our equipment is the ideal addition to your applications in the field of non-destructive material testing.

Complete your selection with suitable accessories and benefit from our many years of experience.

LEAK DETECTION

Vacuum leak detectors of the VSP series enable the quick and safe leak testing of the welded seams of containers, pipelines and many other welded constructions with the help of the bubble test method.

This test method can also be used to check castings for continuous defects (cracks, porosity).

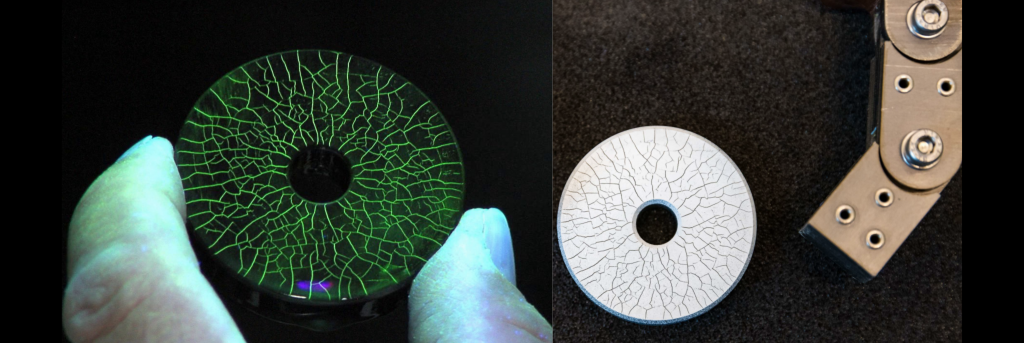

CRACK LUMINESCENCE

Our RILUMINATI products offer an innovative method for the early detection of fatigue / stress cracks.

These are detected as they arise.

SPECIAL PRODUCTS

Our individual solutions for ultrasonic testing and other industrial applications.

LINE OA