ABOUT US

We have always been driven by a spirit of ambitious innovation and a strong bond with our partners. We think there is much more to share than products, materials, and technologies. We wish to share our values and traditions. We share the idea of a great team, in which everyone pulls in the same direction.

Homai Engineer

Chairperson & Managing Director

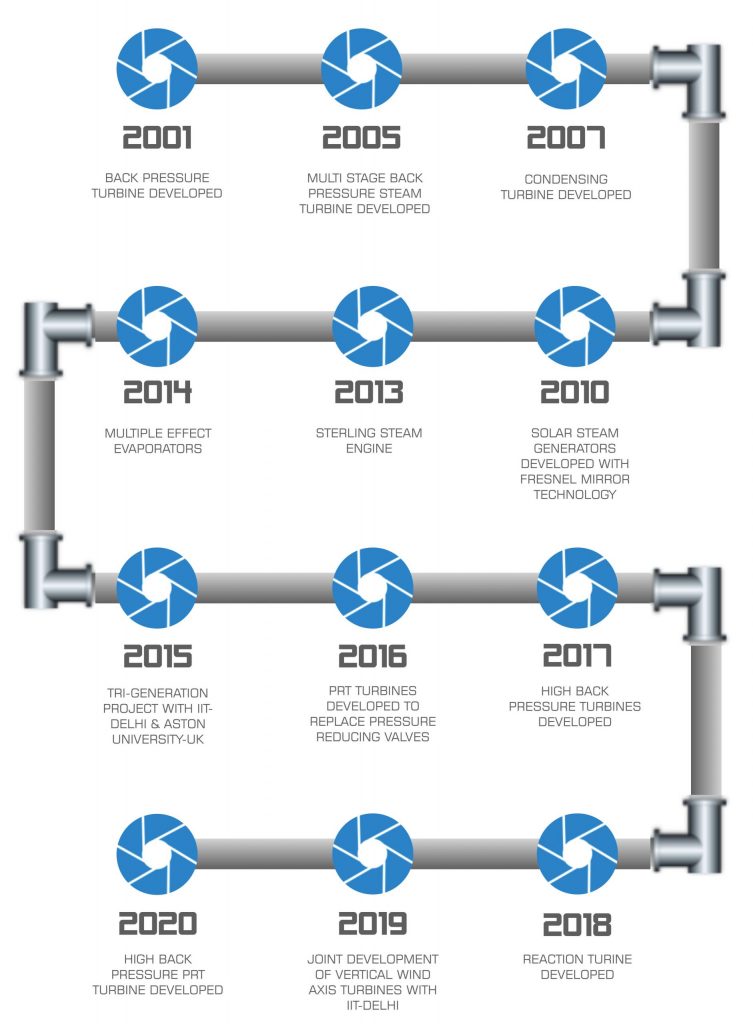

HERITAGE

125 years ago, IBL emerged as a long-standing establishment with a subsequent expansion into boilers and upward integration. With the help of his five sons, Mr. Bomanshaw Homavazir established an engineering workshop at Hubli, Karnataka in 1860. Soon enough, the company’s name broadened, Bomanshaw and his sons were overwhelmed with work from ginning factories and developed an expertise in repairing crankshafts of engines.

These skilled technicians therefore were respectfully called “Engineer Sahab”. Eventually, they adapted ‘Engineer’ as their family name. This laid the foundations of Engineer and Sons. With the advent of the Steam Engine, Engineer and Sons became an importer of Steam operated Road Roller Boilers.

CORPORATE OVERVIEW

Today the IBL group employs over thousand candidates and is the second largest boiler manufacturer in India. The dynamic Homai Engineer who is the Chairperson and Managing Director leads it.

The companies under the IBL group are :

With a vast pool of highly talented and experienced engineers, IBL has continued to maintain its reputation as a Research Powerhouse of Boilers.

PRODUCT

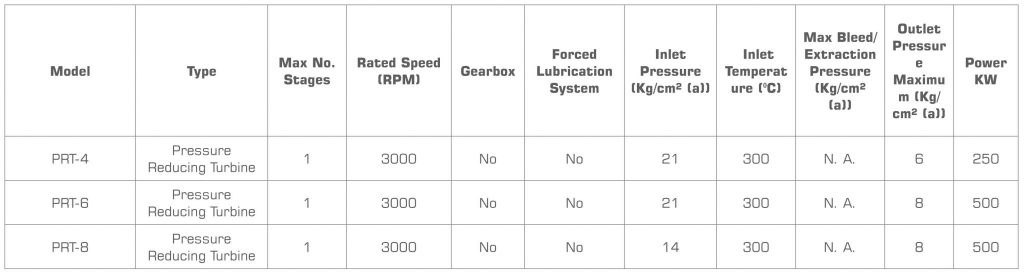

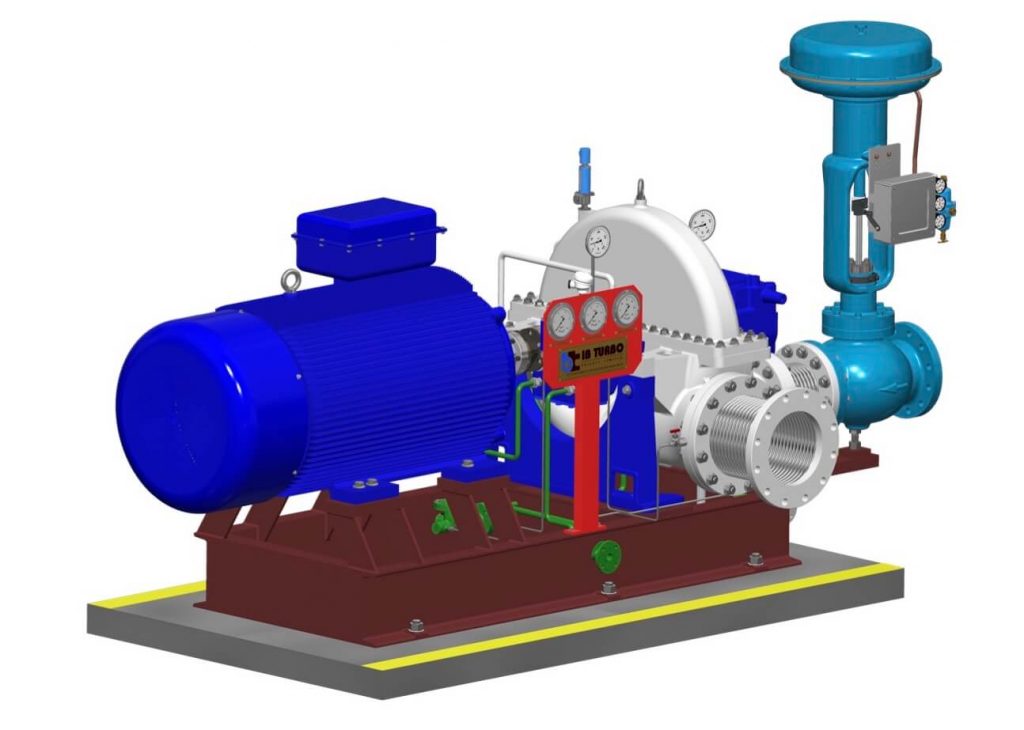

PRESSURE REDUCING TURBINE

The Pressure Reducing Turbine generates electricity by by passing of the Pressure Reducing Station

CONCEPT

FEATURES

CONCEPT

Our PRT is the most popular energy efficiency device for steam users. The flexibility offer by the PRT is unmatched, as it adapts to all operation parameter changes, including variable steam flow, pressure and temperature. Ring lubrication ensures failsafe operation in all conditions.

The induction generator ensures all seamless synchronising and utilisation of power generated. Along with the guidance of our team of engineers, installation is simple, and operation is simple. Most users have reported payback is within 1 year of operation.

FEATURES

- Robust double bearing rotor with 3000 RPM design ensures highest operation reliability

- Horizontally Split Steam casing ensures easy inspection of the internals without disturbing the steam lines.

- Suitable for operation with saturated steam

- Ring Lubricated bearings ensures no requirement for Pressurised oil system.

- Can handle large variations in process steam demand and Boiler pressure.

- Touchscreen Panel ensures ease of operation.

- Induction Generator ensures easy synchronising with Grid.

- Pneumatic control valve ensures optimum process pressure.

- Option of labyrinth and control ring steam seals

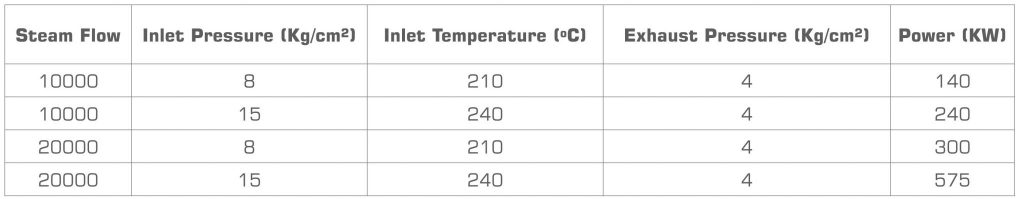

PARAMETERS