FLEXOMIX

CONTINUOUS AGGLOMERATION SYSTEM

Hosokawa Micron provides the powders and bulk solids processing industry with innovative process systems for the agglomeration of fine powders and particles, also called wet granulation or particle size enlargement. Agglomeration solutions are great tools for improving physical properties like flowability, wettability and dispersibility, bulk density and product appearance.

The Flexomix agglomeration system is a compact installation for continuous mixing and agglomeration of powders with liquids. The resulting granulates have a typical particle size of 0.2 to 1.2 mm, a porous, raspberry-like structure, good solubility and good flow properties. Depending on the application, capacities can vary from 50 to 40,000 kg/hour.

Working principle

The Flexomix agglomeration system is a powerful combination of two proven Hosokawa technologies: the Flexomix continuous mixer/agglomerator and the Schugi fluid bed dryer and cooler. This combined design provides optimal process control and makes it the ultimate powder processing solution.

This combination means that base powders can be fed as a mixture or as multiple powders in parallel. An accurate, gravimetrical powder feeding subsystem ensures a constant powder/liquid ratio and a liquid dosing skid ensures accurate flow control and a constant powder/liquid ratio in the agglomerator. This liquid skid can be equipped with a stirrer or a heated tank for example, or in the case of solution binders, a preparation tank.

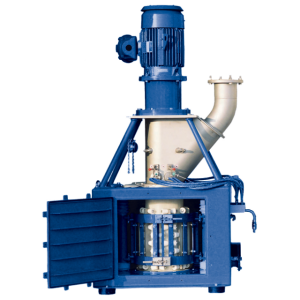

Powders and liquids can be fed into the unit through top inlet(s) using air atomizers which combine with turbulent air flow inside the mixer’s vertical chamber, mixes powdery and liquid particles intensively and instantaneously.

The Flexomix has been designed to be compact whilst allowing for homogeneous mixing of powders and liquids at capacities of up to 40,000 kg/h. To achieve this, the Flexomix has a flexible mixing chamber and a shaft with pitch-adjustable mixing blades that rotate at high speed. The resulting granulates have a porous, raspberry like structure in particle sizes of 0.1 to 1.2 mm and with a D50 between 300 and 700 micron at low to medium density.

Schugi fluid bed dryer

The Flexomix agglomeration system is a powerful combination of two proven Hosokawa technologies: the Flexomix continuous mixer/agglomerator and the Schugi fluid bed dryer and cooler. This combined design provides optimal process control and makes it the ultimate powder processing solution.

This combination means that base powders can be fed as a mixture or as multiple powders in parallel. An accurate, gravimetrical powder feeding subsystem ensures a constant powder/liquid ratio and a liquid dosing skid ensures accurate flow control and a constant powder/liquid ratio in the agglomerator. This liquid skid can be equipped with a stirrer or a heated tank for example, or in the case of solution binders, a preparation tank.

Powders and liquids can be fed into the unit through top inlet(s) using air atomizers which combine with turbulent air flow inside the mixer’s vertical chamber, mixes powdery and liquid particles intensively and instantaneously.

The Flexomix has been designed to be compact whilst allowing for homogeneous mixing of powders and liquids at capacities of up to 40,000 kg/h. To achieve this, the Flexomix has a flexible mixing chamber and a shaft with pitch-adjustable mixing blades that rotate at high speed. The resulting granulates have a porous, raspberry like structure in particle sizes of 0.1 to 1.2 mm and with a D50 between 300 and 700 micron at low to medium density.

- Excellent mixing effect

Flexomix end products are homogenous from sample to sample. Because all ingredients are mixed instantaneously, de-mixing of powders cannot occur. Each sample has a uniform dispersion of liquid(s) and solids that is beyond the capability of conventional mixers.

- Self-cleaning

The external roller cage massages the outside of the mixing chamber to prevent build-up of product on the inside.

- Flexible

As product life cycles shorten, production facilities need to be able to switch easily to the manufacture of other types of products. The Flexomix is designed to handle a wide range of different materials with varying product properties.

- Low manpower requirements

Thanks to the operation of the Flexomix in continuous processing mode, productivity is high and manpower requirements are low. The process is operator-insensitive.

- Maintenance-friendly construction

The clever design of the Flexomix, with a single rotating shaft plus blades and the external roller cage, reduces the maintenance effort. It can be disassembled in less than two minutes and the liquid injectors are easy to remove

The Flexomix Agglomeration System is suitable for a wide range of process applications, including:

- Modification of starch

- Agglomeration of veterinary antibiotics

- Agglomeration pesticide formulae

- Agglomeration of fine powders for compaction

- Hydration of phosphates

- Production of detergent powders

- Finishing of filter cakes

- Instantizing of cocoa drink powder

- Addition of cross-linking agents to Super Absorbent Polymers (SAP)

- Humidifying products (e.g. pesticides) before extrusion

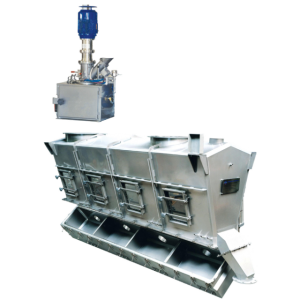

Schugi fluid bed dryers/coolers are available in sizes (air distribution plate area) ranging from 0.25 m² to > 20 m². The required size of the dryer/cooler is generally determined in our test centre and depends on product throughput, evaporation capacity, particle size distribution, air temperatures and final product temperature.

The Flexomix mixer/agglomerator is available in six sizes. Their typical characteristics are described below. Please note that these values are indicative only. Detailed information is available on request.

| Model | [-] | FXD- 100 | FXD- 160 | FXD- 220 | FXD- 250 | FXD- 335 | FXD- 400 |

|---|---|---|---|---|---|---|---|

| Length | [mm] | 520 | 702 | 976 | 976 | 1270 | 1270 |

| Width | [mm] | 650 | 620 | 880 | 880 | 1100 | 1100 |

| Height incl. motor | [mm] | 1265 | 1500 | 1967 | 1967 | 2270 | 2910 |

| Capacity (bulk density 0.5 kg/l) | [kg/h] | 100 – 400 | 250 – 1000 | 800 – 2500 | 2000 – 4000 | 3000 – 10,000 | 8000 – 40,000 |

| Typical motor power | [kW] | 3 | 7.5 | 7.5 – 10 | 11 – 15 | 22 – 45 | 37 – 75 |

- Preparation & Dosing

Liquid premixes can be prepared in the make-up tank and, if multiple powders need to be premixed, a live hopper or Nauta® mixer can be integrated. To guarantee a constant and accurate flow of powder and liquid, high-quality powder dosing feeders and liquid dosing systems are an integral part of the system. - Drying & Cooling

In the static fluid bed dryer, the agglomerates are dried and cooled. After cooling, the product is conveyed to the product classifying section for preparation of the final product. - Classification & Packaging

After classification, the product is split into on-size, over-size and (if needed) fines material. Over-size material can be crushed and fines can be reprocessed if applicable. On-size agglomerates can be stored in big bags or transported to a final packaging line. This whole process takes place in continuous mode. - Air Treatment

The performance and functionality of the fluid bed in combination with the air treatment section is an important part of the agglomeration process as this can have a direct impact on the level of agglomeration and product quality. - Controls & Process Automation

Hosokawa Micron’s systems include optimally integrated hardware and software controls to ensure consistently high product quality under varying circumstances. We can provide ergonomic and visual HMI-PLC panels including lot traceability, operator identification, remote service, alerts and customized data reports to give you full insight into your production processes.

The Flexomix continuous agglomeration system is a powerful combination of a number of functionalities:

- Powder handling system

- Powder dosing system

- Binder dosing system(s): water, steam, and other liquids

- Schugi Flexomix mixer and agglomerator (FX),

- Schugi Fluid Bed Dryer and Cooler (FBD)

- Air system including blower and heating/cooling equipment

- Air exhaust system including cyclone and filter

- Product classification and size crusher (if necessary)

- State-of-the-art integrated control system

When designing an agglomeration system, it is important that agglomeration is not treated as a stand-alone process. That’s why our experts work closely with your team to design an integral production concept that meets your broader needs – both today and in the future. Our approach is based around the clear definition and careful consideration of each individual process step, including storage, conveying, charging, mixing, agglomeration, drying, cooling, discharging, sieving, packing and more. This results in a tailor-made agglomeration system solution that is optimally engineered for you.